Introduction: AI in Manufacturing Is a Workforce Decision, Not Just a Tech Decision

Artificial intelligence (AI) is transforming manufacturing faster than any technology since industrial automation. From predictive maintenance and computer vision quality checks to autonomous scheduling and collaborative robots, AI promises massive productivity gains.

Yet alongside opportunity comes fear. Many workers worry that AI in manufacturing means job losses, deskilling, and increased surveillance. Many leaders worry that failing to adopt AI will make their factories uncompetitive.

The truth is this: AI does not automatically destroy jobs or boost productivity. Outcomes depend on how it is deployed.

Manufacturers that treat AI as a cost-cutting replacement tool often experience resistance, turnover, and operational risk. Those that deploy AI as a human-centred productivity amplifier achieve better results—higher output, improved quality, safer workplaces, and a more resilient workforce.

This article explains how manufacturers can protect jobs while boosting productivity when deploying AI, using proven strategies from real-world factories.

Understanding AI’s Real Impact on Manufacturing Jobs

AI does not eliminate entire occupations overnight. Instead, it automates specific tasks within jobs.

Tasks Most Affected by AI

-

Manual data entry and reporting

-

Routine visual inspections

-

Fixed-schedule maintenance

-

Repetitive material handling

-

Static production planning

Tasks That Remain Human-Led

-

Decision-making under uncertainty

-

Root-cause analysis

-

Continuous improvement

-

Safety judgment

-

Cross-functional coordination

Key insight:

AI shifts what workers do, not whether workers are needed.

Why Productivity and Job Protection Are Not Opposites

A common mistake is viewing productivity gains as coming only from headcount reduction. In reality, the biggest productivity gains come from:

-

Less downtime

-

Higher first-pass yield

-

Faster problem resolution

-

Better asset utilization

-

Reduced rework and scrap

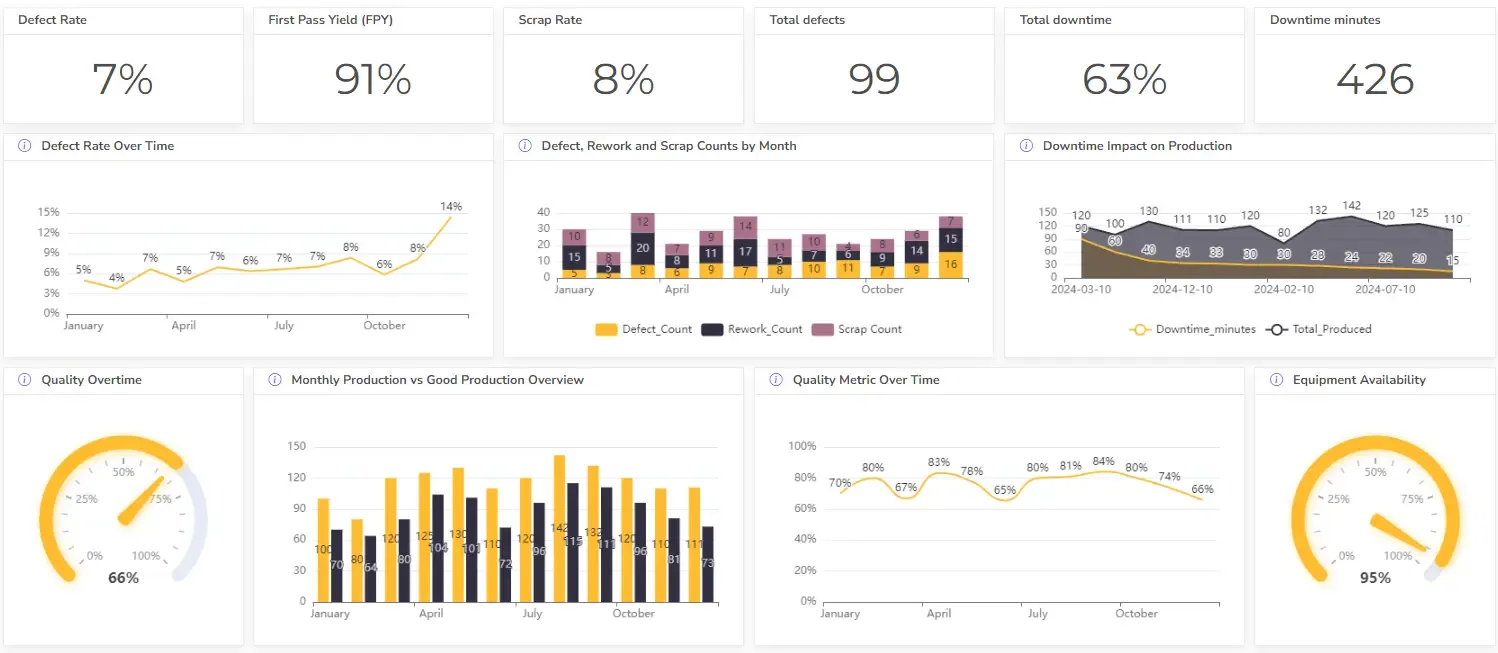

All of these improve when skilled workers are empowered by AI. AI in manufacturing productivity.

1. Use AI to Augment Workers, Not Replace Them

The most successful AI deployments focus on augmentation.

Examples of Augmentation in Manufacturing

Predictive Maintenance

AI analyzes sensor data to predict failures before they occur.

-

Productivity benefit: Reduced unplanned downtime

-

Job protection: Maintenance technicians become reliability experts rather than emergency fixers

AI Vision Quality Inspection

AI flags defects; humans validate and investigate causes.

-

Productivity benefit: Faster inspection at scale

-

Job protection: Quality inspectors shift to process improvement roles

Collaborative Robots (Cobots)

Cobots handle repetitive or heavy tasks alongside humans.

-

Productivity benefit: Higher throughput, fewer injuries

-

Job protection: Operators retain oversight and control

2. Build Job Transformation Maps Before Deployment

Every AI project should include a workforce impact assessment.

Questions to Answer Before Launch

-

Which tasks will AI automate?

-

Which tasks will remain human?

-

Which roles will change?

-

Which new roles will be created?

Common New Roles Created by AI

-

AI system operator

-

Data quality technician

-

Automation supervisor

-

Digital maintenance specialist

-

Human-machine interface designer

This approach reframes AI as career evolution, not displacement.

3. Invest in Reskilling and Upskilling at Scale

AI-enabled factories require continuous learning.

Effective Reskilling Strategies

-

Paid training during work hours

-

Modular micro-learning programs

-

Hands-on pilot projects

-

Certification pathways linked to promotion

High-Value Skills for AI-Driven Manufacturing

-

Data interpretation

-

AI system supervision

-

Root-cause analysis

-

Cross-functional collaboration

-

Cyber-physical system awareness

Business case:

Reskilling costs are significantly lower than recruitment, onboarding, and lost institutional knowledge.

4. Deploy AI Where It Improves Quality, Not Just Speed

Speed without quality destroys value.

High-ROI AI Use Cases

-

Scrap and waste reduction

-

Energy optimization

-

Process consistency

-

Safety monitoring

-

Yield improvement

When workers see AI improving their daily work, adoption increases dramatically.

5. Involve Workers Early and Continuously

AI resistance is usually caused by lack of transparency, not fear of technology.

Best Practices for Worker Involvement

-

Co-design workflows with operators

-

Run pilots with volunteer teams

-

Share performance metrics openly

-

Create feedback loops for improvement

Factories that do this see:

-

Faster adoption

-

Higher system accuracy

-

Fewer workarounds

-

Greater trust

Also Read : Should AI Have Rights? The Ethics Debate Explained

6. Establish Ethical and Operational Guardrails

AI needs boundaries.

Essential AI Guardrails in Manufacturing

-

Humans retain final decision authority

-

No black-box performance evaluation

-

Clear accountability for AI errors

-

Worker data privacy protections

-

Transparent model limitations

These guardrails protect both productivity and trust.

7. Measure Success the Right Way

Avoid measuring AI success solely by labor cost reduction.

Balanced AI Performance Metrics

| Productivity Metrics | Workforce Metrics |

|---|---|

| OEE improvement | Employee retention |

| Downtime reduction | Training completion |

| Yield increase | Internal mobility |

| Energy efficiency | Safety incidents |

| Scrap reduction | Engagement scores |

If both sides improve, the AI strategy is working.

Common Mistakes Manufacturers Make With AI

-

Deploying AI without workforce planning

-

Treating AI as an IT project instead of an operational change

-

Ignoring shop-floor input

-

Underinvesting in training

-

Measuring only short-term cost savings

Avoiding these mistakes dramatically improves outcomes. human-centered AI in manufacturing

Case Example: Human-Centered AI in Action

A mid-sized manufacturing plant deployed AI-driven predictive maintenance:

-

Downtime reduced by 30%

-

Maintenance overtime reduced by 25%

-

Zero layoffs

-

80% of technicians reskilled into reliability roles

The result: higher productivity and higher retention.

The Role of Leadership in AI-Driven Manufacturing

Leadership determines whether AI becomes a threat or a tool.

Effective AI Leadership Principles

-

Communicate early and often

-

Align AI goals with workforce goals

-

Fund training as core infrastructure

-

Reward collaboration, not fear

AI success is cultural before it is technical.

Free Image Sources for This Post

You can safely use images from:

-

Unsplash.com

-

Pexels.com

-

Pixabay.com

Suggested search terms:

-

“AI manufacturing factory”

-

“smart factory workers”

-

“human robot collaboration”

-

“predictive maintenance industry”

(Free for commercial use, no attribution required—check licenses.)

Conclusion: AI Is a Workforce Multiplier When Done Right

AI in manufacturing is inevitable—but job loss is not.

When deployed responsibly, AI:

-

Makes factories more productive

-

Makes jobs safer and more skilled

-

Preserves institutional knowledge

-

Strengthens long-term competitiveness

The manufacturers that win will not be those who replace workers fastest—but those who empower workers best.

AI is not the end of manufacturing jobs.

It is the next chapter of manufacturing work.